Technology Page - MSR Xtreme Shield Tent Coating

Sep 10, 2018

Revolutionary Xtreme Shield Waterproof Coating

We began by looking at industries that require ultra-durable waterproof coatings to protect their products from the elements. Taking cues from their coating formulas, we developed a coating that’s revolutionary for the tent industry. We’re calling it Xtreme Shield.

How is it different?

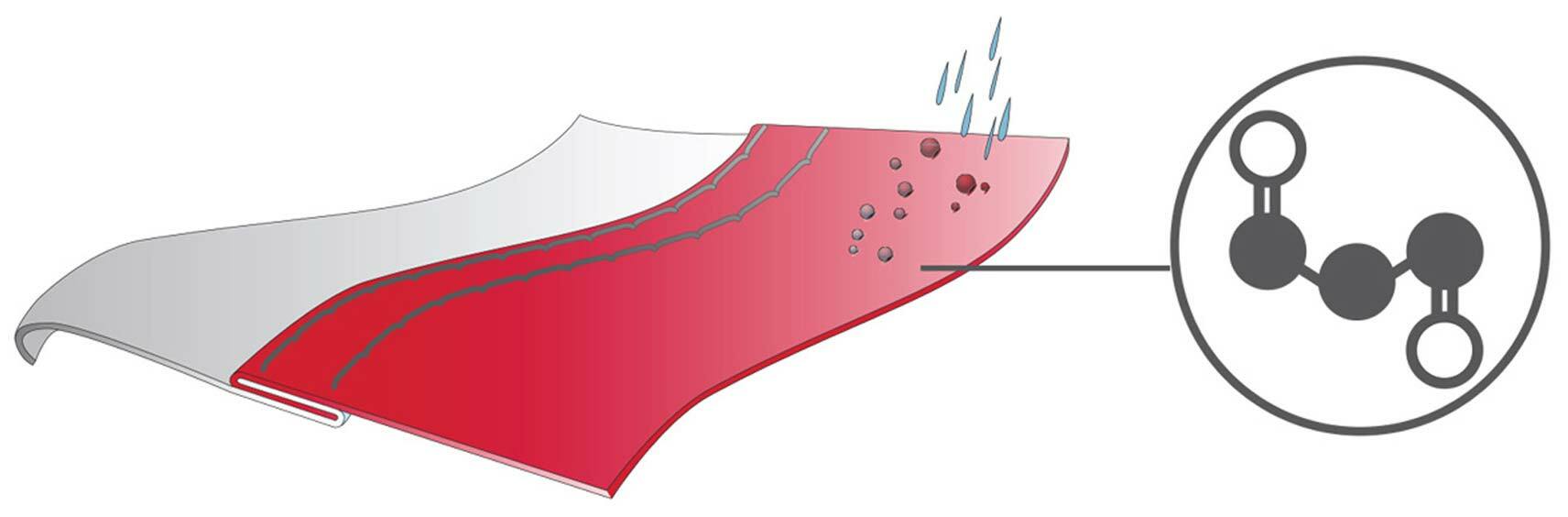

The magic is at the molecular level. Xtreme Shield’s polyurethane features a molecular chain that’s formulated specifically to hold up against heat and humidity. Therefore, it resists the premature degradation that traditional tent polyurethane coatings experience.

For you, this means a tent that lasts much longer, with a quality that’s maintained over time. In fact, this waterproof coating is 3 times more durable than standard coatings, giving you reliable weather protection season in and season out.

Developing the formula, however, was the easy part. It took years of testing to learn how to apply Xtreme Shield to tent fabrics in the production process. Now, having proven its performance, we’re excited this coating continues MSR’s efforts to deliver long-lasting gear you can trust.

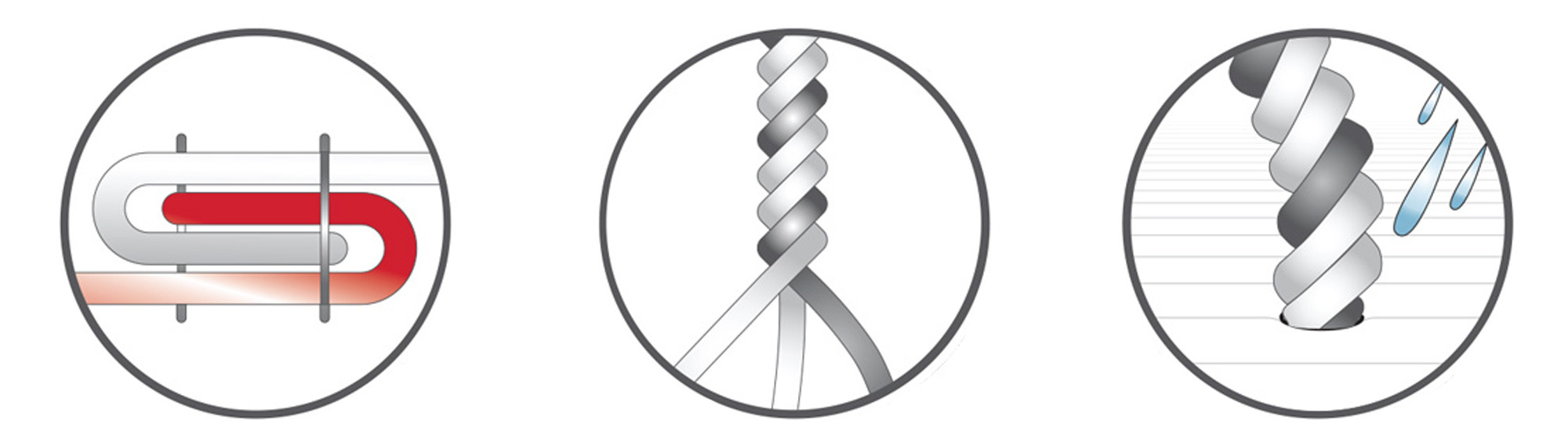

Durable, Long-Lasting Seams

To address the seam tape flaking issue, we use a precision-stitched, factory-sealed seam that’s not only more durable than a taped seam, but can be maintained over time if need-be to ensure it provides watertight protection over the life of your tent.

What makes the construction so durable?

For starters, we use a lap-felled seam, which is extremely strong. Secondly, our meticulous stitching creates a tiny, precise hole. Finally, we go back to a tried-and-true poly-cotton thread blend that swells when wet, a thread proven in the rugged tents of the past. As an extra measure of defense, we add a seam sealing step at the factory, which ensures the tent is rock-solid and reliably watertight out of the bag regardless of the environment you plan to use it in.

While taped seams degrade and peel off over time, ruining your tent, our stiched seams can be cared for over the long-term. As your tent ages, adding sealant to any areas affected by wear will keep your seams performing well for years to come.

Such quality construction demands the careful craftsmanship that we’ve always built into MSR products and we’re proud to once again offer the level of long-term performance you expect from MSR.

When developing the longer-lasting coating, we knew we’d need seams that held up just as long.

Innovation Begins at the End of Comfort Zones

While dropping seam tape feels like a bold move, we’ve never been ones to follow the status quo when a better solution exists. Our goal has been a singular one: deliver gear you can rely on long-term. On today’s lightweight tents, seam tape is often a short-term solution, like a band aid over the seam.

Instead, we believe your tent is an investment and should be built to last. With the Xtreme Shield waterproof coating and a far more durable stitched and factory-sealed seam, we’re proud to say MSR’s lightweight tents deliver our superior quality for longer—staying in the field, out of repair shops and out of landfills.

Xtreme Shield System FAQ

What exactly is the Xtreme Shield System?

The Xtreme Shield System is a superior construction that combines two premium elements: a revolutionary waterproof coating that lasts up to 3x longer than standard coatings; and durable, precision-stitched seams. Working together, they create a system that ensures the weather protection and quality of your tent lasts longer than ever before.

Why did MSR develop it?

As backpacking tents have gotten lighter, they've brought with them two challenges: Their waterproof coatings are more susceptible to hydrolysis, the breakdown of the coating due to moisture, heat and humidity - which causes the coating to become sticky and fail. Secondly, their seam tape eventually falls off, leaving users stranded with no defense.

What makes the seams so durable?

For starters, we use a lap felled seam, which places one edge of the fabric inside a folded edge before it’s stitched down. This creates a very strong seam. Secondly, we use a meticulous stitching technique that creates a tiny, precise hole. Finally, we use a poly-cotton thread blend that swells when it gets wet. Together, they work to create a robust seam that lasts the life of our tent.

Why doesn't MSR seam seal at the factory?

Under most conditions, MSR tents deliver excellent weatherproof protection. From our experience and testing, water infiltration tends to be mainly on the rainfly and on small sections of the seams. By allowing the customer to apply seam sealer themselves only when and where necessary, we reduce the use of chemicals used in our manufacturing process.

How big of an industry issue is this?

Companies industry-wide cite coating degradation and seam-taping failure as one of their biggest contributors to warranties and frustrated customers. For over a decade, MSR has been researching solutions to the problem. Several years ago, we identified a coating that is specifically formulated to combat hydrolysis, and worked to refine it for our manufacturing process. Now proven in the market, we’re expanding this Xtreme Shield solution to more models.

What makes the waterproof coating different from others?

The coating formulation is unique in the industry at the molecular level. To develop it, we researched industries that required ultra-durable waterproof coatings that resist hydrolysis. This led us to our specially formulated Xtreme Shield polyurethane, which has a molecular construction designed specifically to resist degradation due to heat and humidity.

Do I absolutely need to seam seal the tent?

In most conditions, the Xtreme Shield System offers excellent weather protection from the elements. If you anticipate periods of heavy or extended rain, we do recommend seam sealing to ensure you won’t get any drops in your tent. In such conditions, some drops can work their way into the rainfly seams. We believe this isn’t reason enough to sacrifice the longevity of your tent for the short-lived performance of seam taping, which leaves you with a leaky tent when it fails.

We began by looking at industries that require ultra-durable waterproof coatings to protect their products from the elements. Taking cues from their coating formulas, we developed a coating that’s revolutionary for the tent industry. We’re calling it Xtreme Shield. How is it different? The magic is at the molecular level. Xtreme Shield’s polyurethane features a molecular chain that’s formulated specifically to hold up against heat and humidity. Therefore, it resists the premature degradation that traditional tent polyurethane coatings experience.